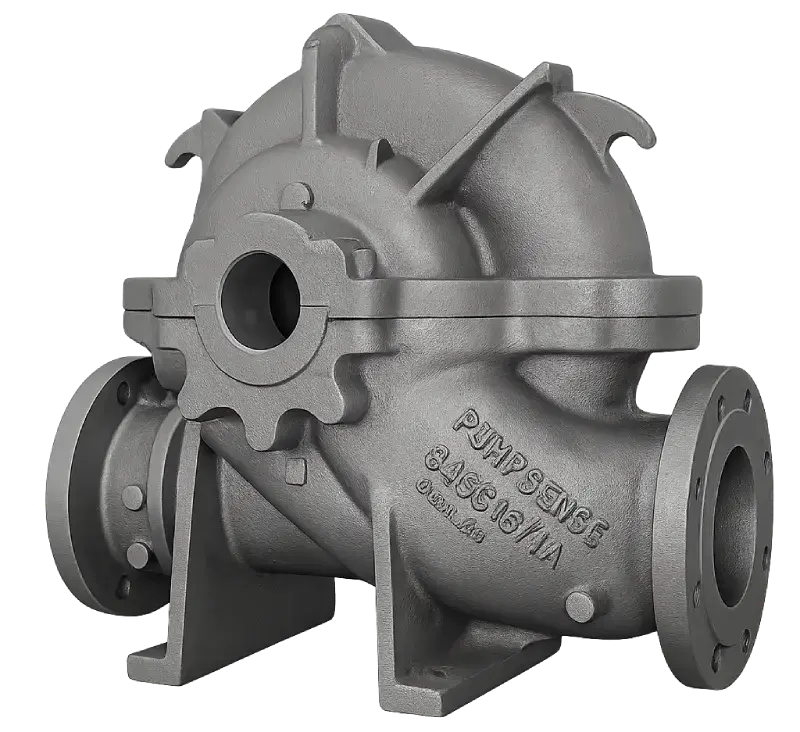

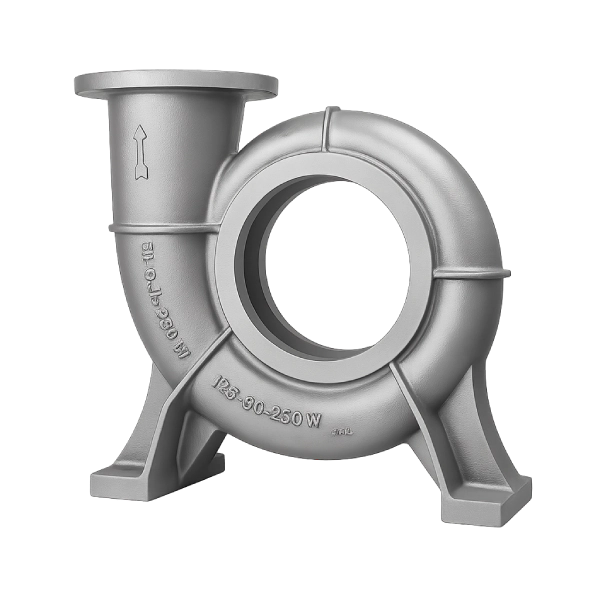

High-quality steel and alloy castings for pumps, valves, and critical industries — delivering reliability, precision, and on-time performance. We also provide high-accuracy CNC solutions for automotive, aerospace, and more....

Customers

Years running our legacy unit (Nikam Precision Cast)

Single-Piece Casting Capability

Alchemy Precision Cast Pvt. Ltd. is a modern steel and alloy steel foundry based in Chakan MIDC, Pune, strategically located near key transport hubs for efficient logistics and on-time deliveries.

We specialize in the manufacture and supply of high-quality Steel, Alloy Steel, and Super Alloy Castings, catering primarily to the Pumps, Valves, and General Engineering Industries. Our new, modernized plant is equipped with:

We go above and beyond to ensure that every customer is satisfied

Our skilled professionals handle every job with skill and precision.

Happily served more than 200+ customers across country

Appropriate Racks are available to store more than 5000 patterns precisely and also increasing the nos. day by day. In-house facility of the repair, rectify and match plating the patterns.

Read More

10 MTs/Hr continuous sand mixer having no bake molding

Various sizes of induction furnaces as follows-

The Knockout Machine is a robust and efficient system designed to separate castings from sand molds after the metal casting process.

The Shot Blasting Machine is an essential surface preparation tool, designed to clean, strengthen (peen), or polish metal surfaces before further processing or finishing. This model features:

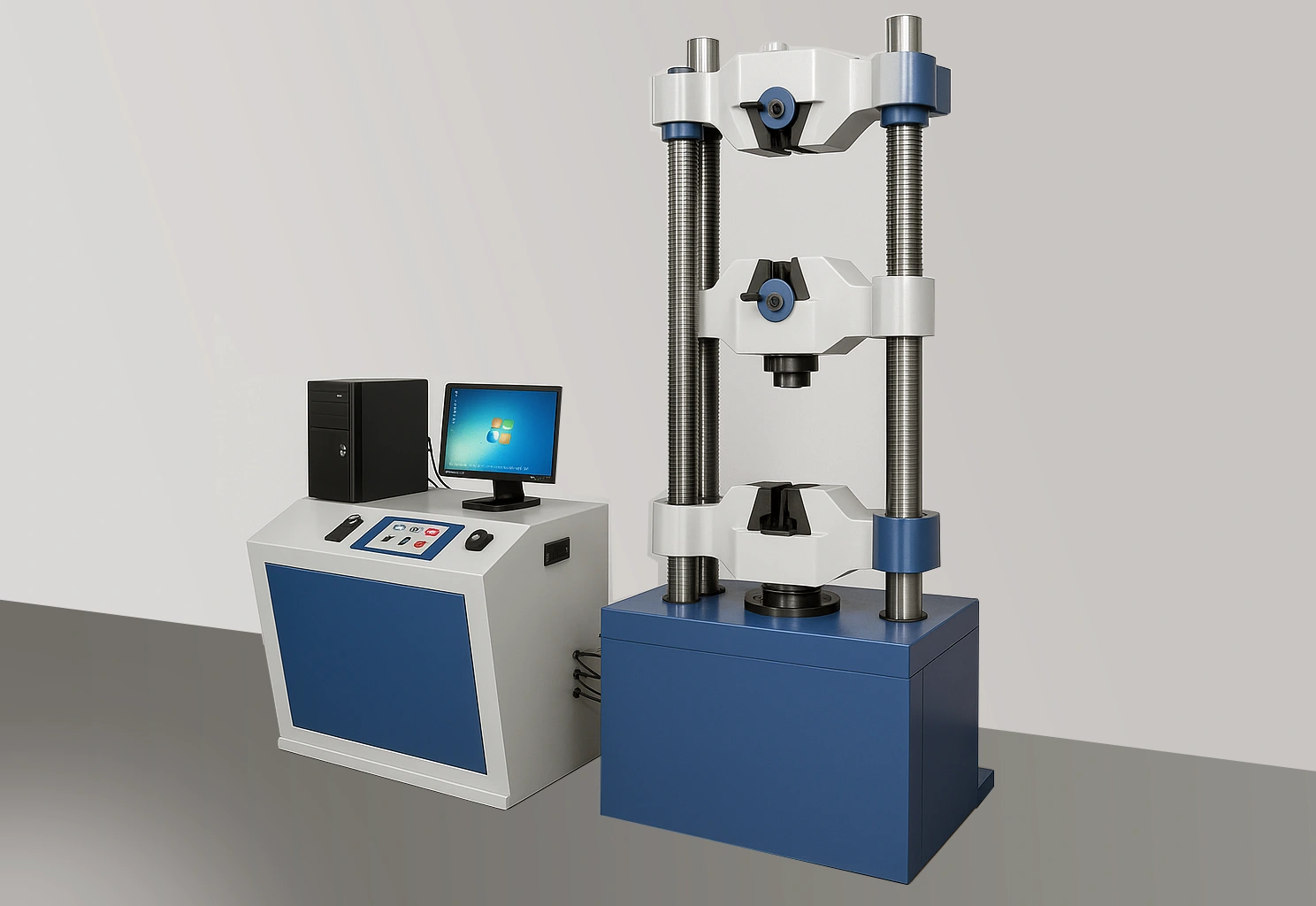

Alchemy Precision Cast employs a Universal Testing Machine (UTM) sourced from Royal Enterprises, designed for high-precision material testing.

At Alchemy Precision Cast, we utilize a robust Impact Testing Machine to determine the toughness and resilience of materials under sudden impact loads.

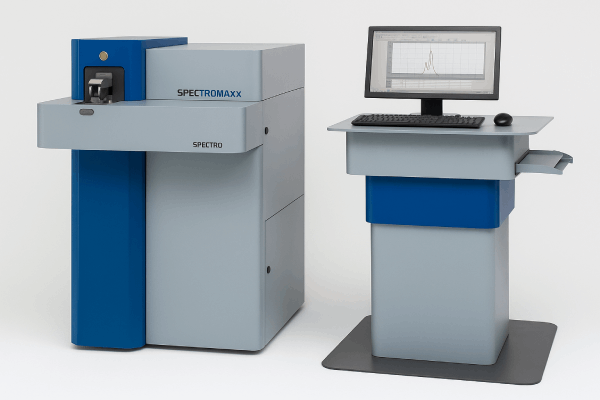

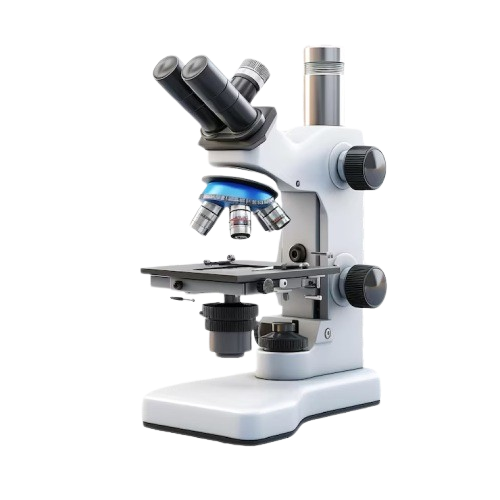

To ensure the highest level of material integrity and compliance with stringent quality standards, Alchemy Precision Cast is equipped with advanced metallurgical testing technology.

Our sand testing laboratory is equipped with advanced tools to ensure the highest quality. The facilities include:

Corrosion testing is performed as per ASTM A262 Practices A, B, C, E, and F to evaluate susceptibility to intergranular attack in austenitic stainless steels. Practice A (oxalic acid etch) is used for screening, while Practices B and E (Streicher and Strauss tests) involve immersion in acid solutions to assess corrosion resistance. Practice C (Huey test) detects chromium depletion, and Practice F confirms results from Practice A.

Read More

Microstructure examination is carried out using optical microscopy at magnifications up to 500x to evaluate grain structure, phase distribution, and detect any defects such as inclusions, porosity, or carbide precipitation. The sample is prepared by sectioning, mounting, polishing, and etching in accordance with ASTM E3 and ASTM E407 standards.

Read More

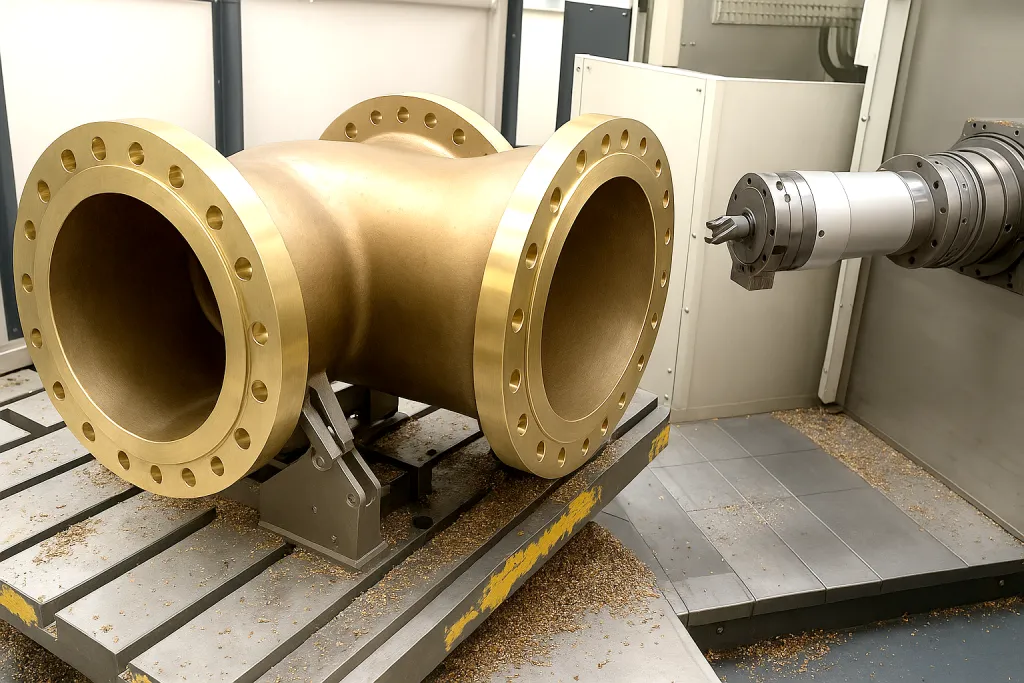

At Alchemy Precision Cast, we ensure that all machining operations meet the highest standards of quality and precision, critical for delivering finished components ready for end-use applications. From outsourced, from approved suppliers only.

Read More

Our castings power the world’s toughest machinery and critical operations.

Let’s create something enduring together.

Products