Melting Capacity :

Melting - Various sizes of induction furnaces as follows -

- 175kw panel with300kg and 150kg furnace

- 450kw with 1500kg and 750 kg furnace

- Laddles-50Kg, 90Kg, 150Kg, 500Kg, Spout ladle & 1500 Kg bottom pouring ladle.

- Ladle preheater

- Bath sample analysis of each heat is done

Simulation Software :

Simulation software allows modelling of thermal heat transfer including radiation with few factors, liquid flow.

Pattern Storage:

Appropriate Racks are available to store more than 5000 patterns precisely and also increasing the nos. day by day. In-house facility of the repair, rectify and match plating the patterns.

Moulding :

- Core "oven set for core heating

- 10 MT/hr continuous sand mixer having no-bake moulding

- 300 kg, 150 kg, 90 kg batch mixer available for core making.

Knockout :

- 6 MTs/Hr vibro-knockout machine having mechanical reclamation plant

Heat Treatment :

- 500 Kgs gas fired Boqqie hearth

furnace - 1500 kgs electric heat treatment furnace with rapid auto quenching manipulator

- Heat treatment furnace calibrated as per API6D/6A

- Water quenching facility with mechanical agitation

Fettling Treatment :

- Shot blasting Machine 1.5 ton and 500kg lifting capacity.

- Different sizes of swing frames & hand grinders

- Arc cutting Machine

- Qualifies Welders

- Picking & Passivation for Stainless Steel Casting

- WPS and PQR done in different alloys under witness by TPI agenesis

- Arc Gouging Machine

- Electronic welding Machine

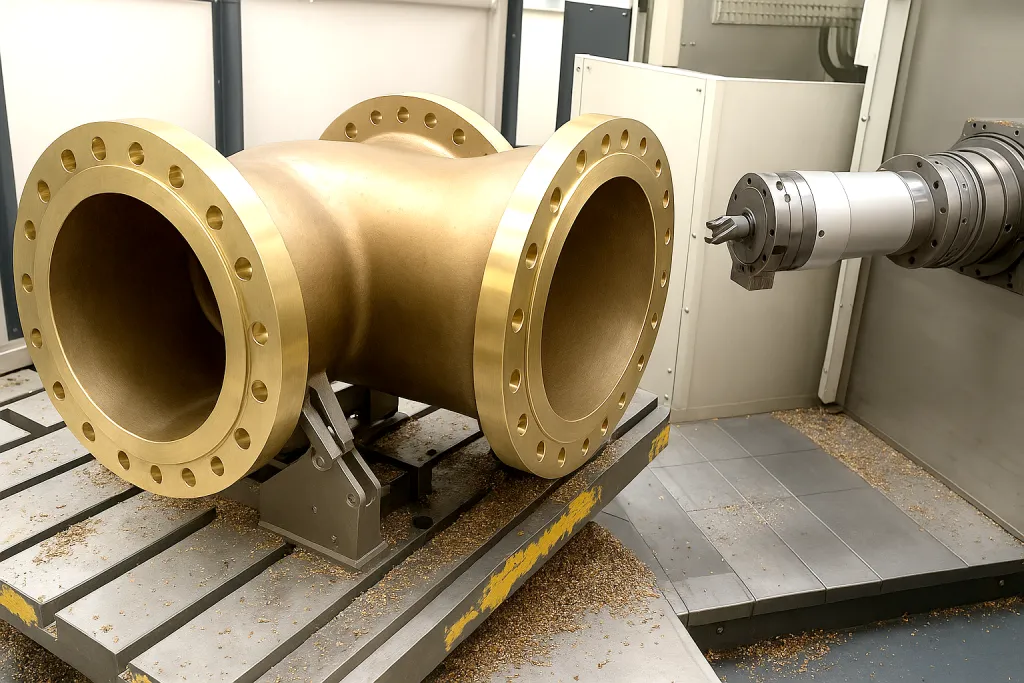

Machining :

At Alchemy Precision Cast, we ensure that all machining operations meet the highest standards of quality and precision, critical for delivering finished components ready for end-use applications. From outsourced, from approved suppliers only.